- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

ធ្នូ . 11, 2024 11:51 Back to list

german style hose clamps factories

The Rise of German Style Hose Clamps A Look at Manufacturing and Innovation

In the world of industrial and automotive applications, the importance of reliable hose clamps cannot be overstated. Among the myriad designs available, German style hose clamps have distinguished themselves through their robust engineering and quality craftsmanship. This article delves into the dynamics of German style hose clamp manufacturing, exploring the factories that produce them and the innovative techniques that set them apart.

Understanding German Style Hose Clamps

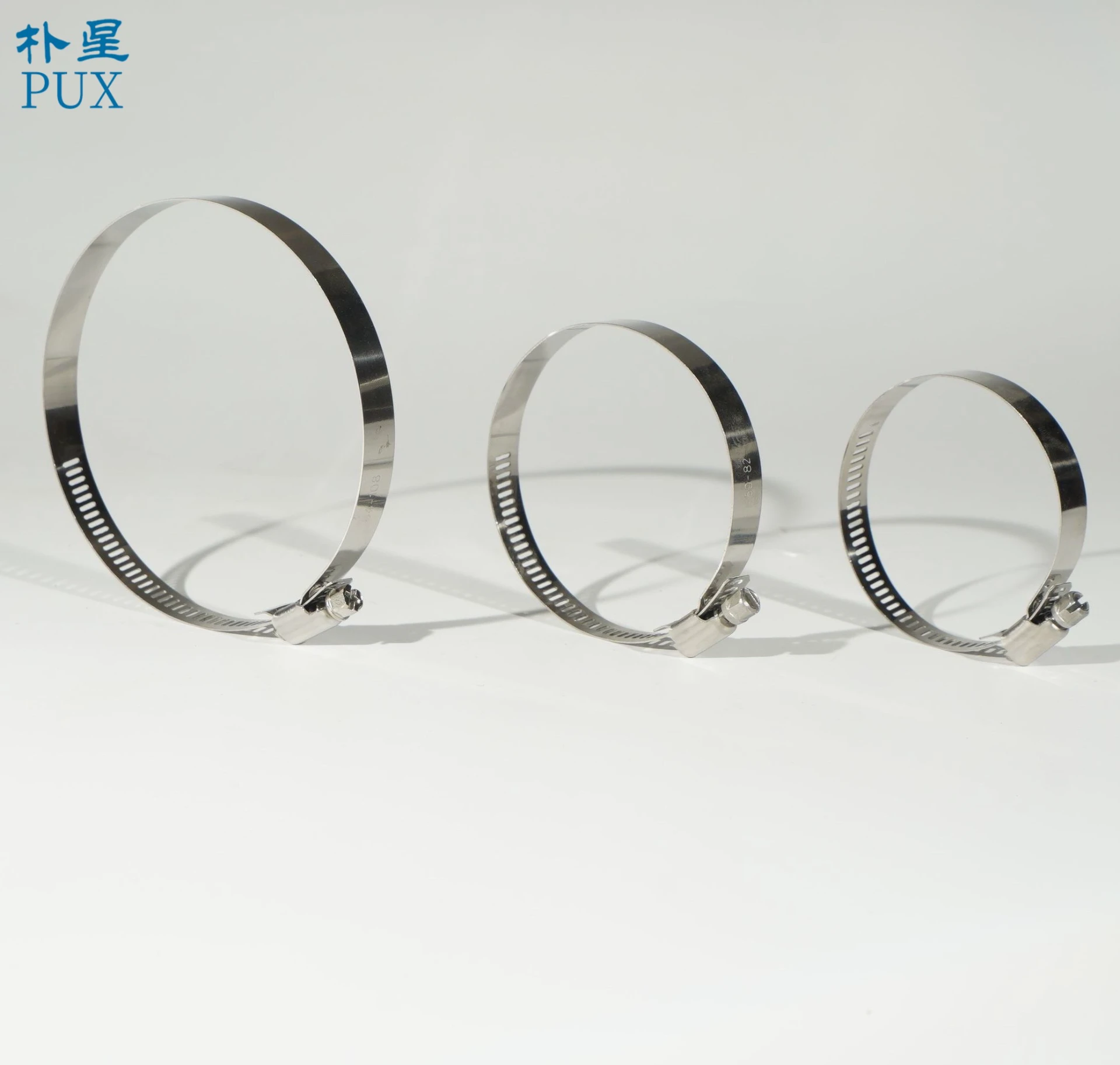

German style hose clamps, often recognized for their unique design and functionality, typically feature a band that is made from high-quality stainless steel, a housing that allows for easy adjustment, and a mechanism that securely holds hoses in place. Their design not only ensures a tight fit but also offers resistance to corrosion, making them ideal for various applications in automotive, industrial, and home settings.

One notable feature is the wider band, which distributes pressure more evenly across the hose surface, minimizing the risk of damage. Coupled with a smooth inner surface, these clamps are prized for their ability to maintain consistent performance over time, underscoring their reliability in demanding environments.

Overview of Manufacturing Facilities

The production of German style hose clamps is predominantly centered in Germany, known for its advanced manufacturing technologies and stringent quality standards

. Renowned factories employ a combination of traditional craftsmanship and modern automation techniques to produce these clamps at scale.In factories across regions such as Baden-Württemberg and Bavaria, skilled workers collaborate with cutting-edge machinery, including CNC machines and automated assembly lines. These facilities focus on efficiency while maintaining high levels of quality control. Each step of the manufacturing process— from material selection to final inspection— is conducted with precision, ensuring that every clamp meets the rigorous demands of the industry.

Innovation in Materials and Design

german style hose clamps factories

The evolution of manufacturing technologies has brought about significant changes in the materials used for hose clamps. German manufacturers prioritize high-grade stainless steel, which not only enhances durability but also promotes resistance to rust and other environmental factors. Some facilities are now exploring alternative materials, such as advanced polymers, which provide weight savings without compromising strength or reliability.

Innovation extends beyond materials; the design of German style hose clamps is continuously being refined. Modern designs incorporate features such as quick-release mechanisms and ergonomic adjustments, which enhance ease of use and installation. This user-centric approach is evident in the factories’ development process, where engineers and designers work closely to address customer feedback and market demands.

The Global Impact of German Manufacturing

While German style hose clamps are celebrated for their quality, their impact extends far beyond Germany’s borders. With the globalization of trade, these clamps have found their place in markets around the world. Manufacturers are increasingly exporting their products to North America, Asia, and beyond. The reputation for quality associated with Made in Germany products adds to the desirability of these hose clamps, resulting in growing international demand.

Moreover, the German manufacturing ethos— a commitment to quality and sustainability— inspires other countries to elevate their production standards. Factories that produce German style hose clamps often adhere to stringent environmental regulations, striving to minimize waste and energy consumption throughout the manufacturing process.

Conclusion

The factories producing German style hose clamps are at the forefront of innovation, combining traditional craftsmanship with advanced technology to create products that meet the challenges of modern applications. With a focus on quality, durability, and user-friendliness, these clamps are not only essential components in many systems but also exemplify the high standards of German engineering.

As industries continue to evolve, the role of hose clamps will remain critical, and the ongoing developments in their design and manufacturing will ensure that German style hose clamps continue to lead the way in reliability and performance. Whether in automotive applications or industrial settings, the legacy of quality from German factories is sure to endure, making them a preferred choice for professionals and enthusiasts alike.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025