- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

សីហា . 13, 2024 09:32 Back to list

Exploring Innovative Hose Clamps Without Screws for Efficient and Durable Applications in Various Industries

The Evolution of Hose Clamps Without Screws A Modern Manufacturing Perspective

Hose clamps play a crucial role in securing hoses in various applications, from automotive industries to household plumbing. Traditionally, hose clamps have utilized screws as a primary method of adjustment and fastening. However, the emergence of screwless hose clamps represents an innovative and efficient leap forward in manufacturing and application reliability. This article explores the features, benefits, and production aspects of screwless hose clamps.

Understanding Hose Clamps

Hose clamps are devices designed to hold a hose onto a fitting. They can be found in engines, fuel delivery systems, and hydraulic applications. The conventional screw-type hose clamps employ threading systems that can be cumbersome and are prone to loosening over time due to vibrations and thermal cycling. As industries evolve, the need for more effective and durable solutions has become evident, leading to the development of hose clamps without screws.

Advantages of Screwless Hose Clamps

Screwless hose clamps offer a range of benefits over traditional designs. First and foremost, they provide a more uniform compression around the hose, which reduces the risk of leaks and enhances sealing efficacy. By eliminating the screw mechanism, these clamps can be installed more quickly and easily—thereby saving valuable time during the assembly process.

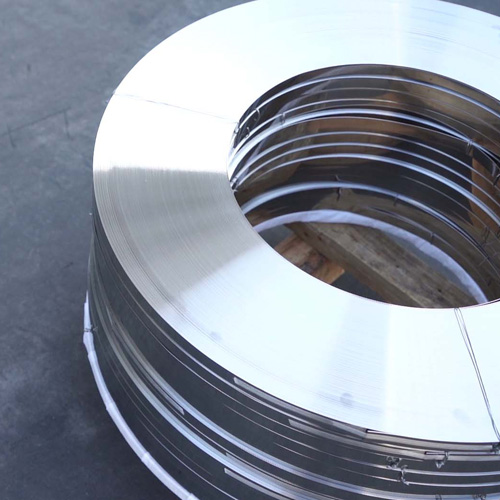

Another significant advantage of screwless designs is their ability to adapt to various hose sizes without needing adjustment. This versatility is particularly beneficial for factories where different hose specifications are frequently employed. Moreover, since screwless hose clamps are typically made from resilient materials like stainless steel or reinforced polymer, they can withstand extreme temperatures and corrosive environments, extending their usability in demanding applications.

hose clamp without screw factories

Sustainability and Durability

In today’s manufacturing ethos, sustainability is paramount. Screwless hose clamps often embody this principle. By reducing the number of components and eliminating screws, manufacturers can decrease material waste. Additionally, these clamps are typically designed for long-term use, which means fewer replacements are needed over time. This durability supports a more sustainable lifecycle for industrial products, aligning with global initiatives to reduce environmental footprints.

Manufacturing Innovations

The production of screwless hose clamps has also evolved. Factories specializing in these advanced clamps leverage cutting-edge techniques, such as injection molding and precision stamping, to produce high-quality components efficiently. These manufacturing processes allow for the creation of complex designs that would be difficult or impossible to achieve with traditional methods. Furthermore, with advancements in automation and industry 4.0 technologies, manufacturers can ensure consistent quality while minimizing labor costs.

Innovation doesn’t stop at the production line; design thinkers are continuously exploring new materials and shapes to further optimize hose clamp performance. This constant evolution reflects the dynamic nature of the manufacturing sector, which remains responsive to industry demands and technological advancements.

Conclusion

Screwless hose clamps represent a significant development in the field of hose fastening solutions. Their advantages—enhanced sealing, ease of installation, sustainability, and sophisticated manufacturing processes—highlight how industry leaders are pivoting toward more innovative and effective products. As manufacturers continue to refine their techniques and materials, screwless hose clamps are poised to become increasingly prevalent in a wide range of applications. The future of hose fastening is here, and it’s free of screws, paving the way for improved performance and reliability across various industries.

-

Durable Hose Clamps with GPT-4 Turbo Tech | Secure Sealing

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&High Breaking Torque

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Industrial Applications

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | High Breaking Torque & Corrosion Resistance

NewsJul.30,2025