- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

ធ្នូ . 15, 2024 16:49 Back to list

Top Suppliers for 4 Inch Black Hose Clamps Available Now

The Importance of Quality Hose Clamps A Spotlight on 4% Black Hose Clamps

When it comes to securing hoses in various applications, hose clamps are indispensable components in many industries, including automotive, plumbing, and manufacturing. Among the myriad of hose clamps available on the market, 4% black hose clamps have gained significant popularity due to their unique features and advantages. This article explores the importance of quality hose clamps, the distinct characteristics of 4% black hose clamps, and tips for sourcing reliable suppliers.

Hose clamps serve the primary function of firmly securing hoses to fittings, preventing leaks and ensuring that systems function efficiently. Quality hose clamps not only enhance the durability of connections but also improve the overall safety of operations. With a proper hose clamp in place, you can avoid costly equipment failures that often arise from loose or inadequately secured hoses.

The term 4% black hose clamps refers to a specific type of clamp that typically features a black coating, which can be advantageous for various reasons. One of the main benefits of the black finish is its resistance to corrosion. In many applications, especially in harsh environments involving exposure to moisture, chemicals, or high temperatures, hose clamps can suffer from rust and degradation. A black coating, often made from powder coating or electroplating, helps extend the lifespan of the product by providing an additional layer of protection against corrosive elements.

Another significant advantage of 4% black hose clamps is their aesthetic appeal. In industries where appearance matters—such as automotive modifications or high-end plumbing installations—the sleek black finish can provide a more polished and finished look. This subtle enhancement is increasingly important for consumers and professionals who seek to maintain a certain standard in their projects.

Sourcing quality 4% black hose clamps requires careful consideration of suppliers. Not all hose clamps are created equal, and the safety and performance of your systems directly depend on the quality of the components you use. Here are some tips for finding reliable hose clamp suppliers

1. Reputation and Reviews Research potential suppliers by reading reviews and testimonials from previous customers. Established suppliers with a good reputation are more likely to provide high-quality products.

4 black hose clamps supplier

2. Material Quality Inquire about the materials used in the manufacture of the hose clamps. High-grade stainless steel or specialized alloys are ideal for durability and corrosion resistance.

3. Testing and Certification Ensure that the suppliers you are considering perform rigorous testing on their products and comply with industry standards. Certifications can provide additional assurance of the quality and reliability of their hose clamps.

4. Product Range A supplier that offers a wide range of hose clamps—including various sizes, materials, and finishes—may be better positioned to meet your specific needs.

5. Customer Service Good customer service is crucial when dealing with suppliers. They should provide responsive and knowledgeable support to assist you in selecting the right products for your applications.

6. Pricing and Bulk Discounts Compare prices among various suppliers. While cost is an essential factor, it should not come at the expense of quality. Look for suppliers that offer competitive pricing and bulk order discounts.

In conclusion, 4% black hose clamps are a valuable addition to any toolkit, providing both aesthetic appeal and robust performance. Their corrosion-resistant properties and sleek finish make them suitable for various applications. By sourcing these clamps from reputable suppliers, you can ensure that your systems operate safely and effectively, minimizing the risk of failures and extending the life of your equipment. As you explore the market for hose clamps, prioritize quality, reliability, and customer service to achieve the best results.

-

Premium Stainless Steel Hose Clamp for Automotive & Industrial Use

NewsJul.27,2025

-

Heavy Duty Hose Clamp – Durable Stainless Steel Automotive Tube Clip

NewsJul.26,2025

-

High Quality Precision Stainless Steel Strip for Industrial Use

NewsJul.25,2025

-

Black Rubber Hose Clamp with Rubber Lined & Insulated Design for Secure Fitting

NewsJul.24,2025

-

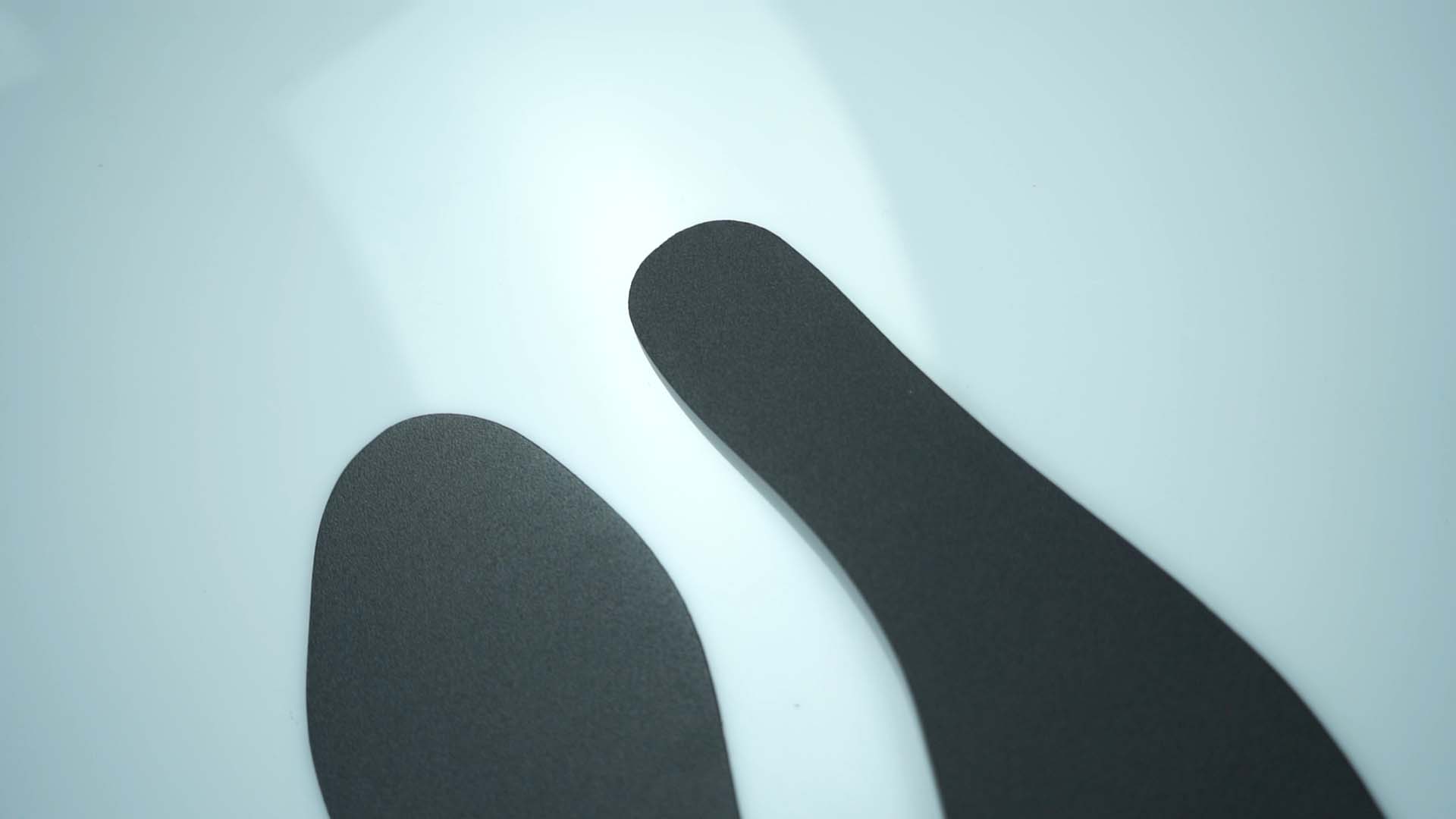

High Quality Steel Stainless Midsole for Safety Shoes Supplier

NewsJul.23,2025

-

High Quality Hose Clamps Mini Clips - German Style & Stainless Steel

NewsJul.22,2025