- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 07, 2024 17:34 Back to list

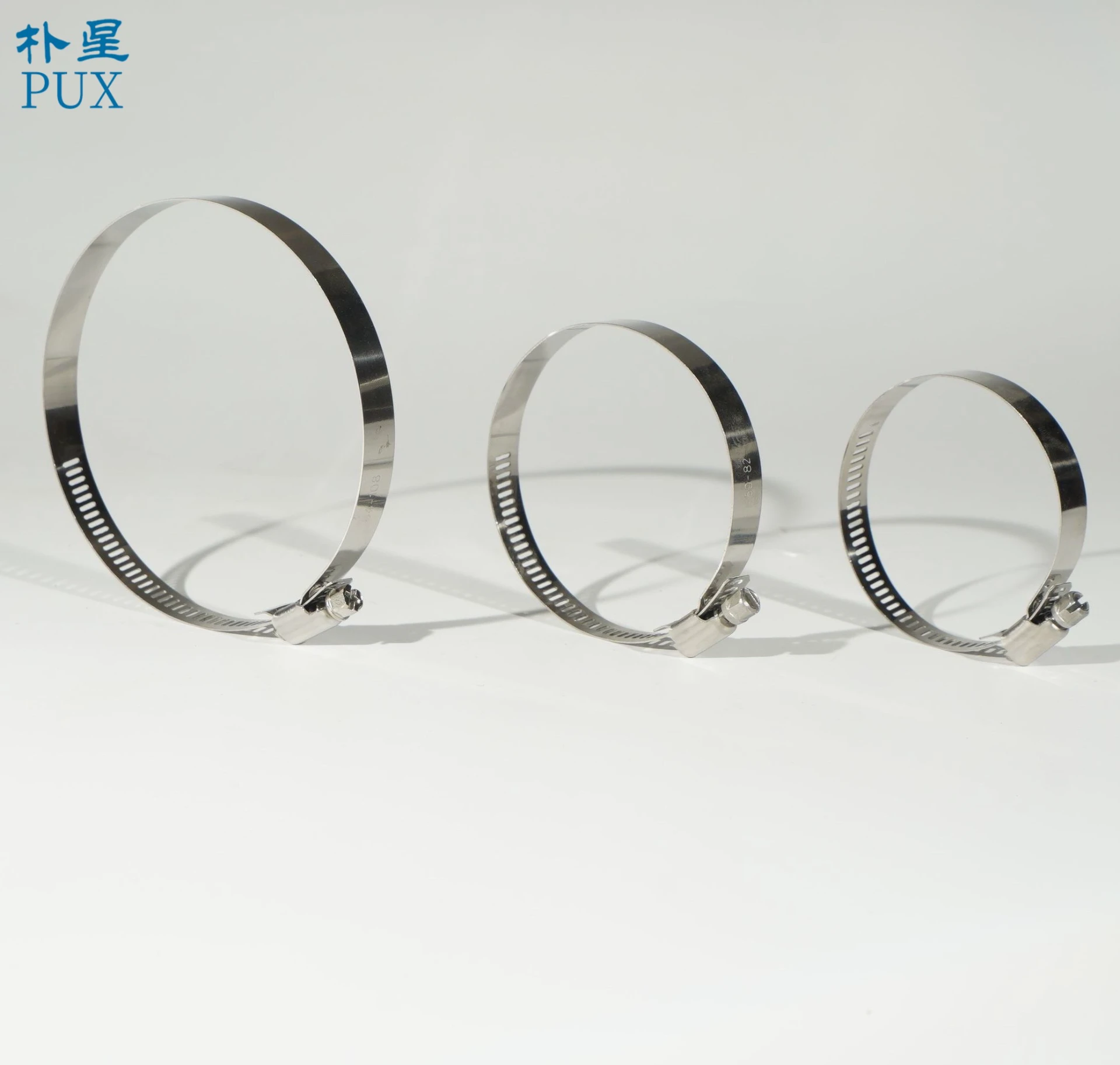

Quality GM Hose Clamps for Reliable Automotive Performance and Durable Solutions

Understanding GM Hose Clamps Essential Components for Automotive Applications

Hose clamps are vital components in automotive and industrial applications, designed to hold hoses securely in place and prevent fluid leaks. Among the various types of hose clamps available, GM (General Motors) hose clamps have gained recognition for their reliability and effectiveness in various vehicles produced by the automotive giant. This article delves into the functionality, types, and applications of GM hose clamps, highlighting their importance in maintaining vehicle performance.

The Purpose of Hose Clamps

Hose clamps serve a fundamental purpose they secure hoses to fittings, ensuring that fluids—whether they be oil, coolant, or fuel—remain contained within designated pathways. A well-functioning hose clamp prevents leakage, which could lead to engine overheating, loss of power, or even catastrophic failures. In automotive applications, where precision and reliability are paramount, high-quality hose clamps, such as those made for GM vehicles, play a crucial role.

Types of GM Hose Clamps

There are several types of hose clamps utilized in GM vehicles, each designed for specific applications and hose types. The most common types include

1. Spring Clamps These clamps are made from spring steel and provide a constant, equal pressure around the hose, making them an excellent choice for high-pressure applications. They are often used in radiator and fuel lines.

2. Screw (or Worm Gear) Clamps Screw clamps consist of a band wrapped around the hose, with a screw mechanism that allows for tight adjustment. These are versatile and easy to install, making them popular in various automotive applications.

gm hose clamps

3. Quarter-Turn Clamps Used primarily where quick disassembly is required, quarter-turn clamps allow for easy removal and reinstallation, which is beneficial in maintenance situations.

4. T-Bolt Clamps Ideal for high-performance applications where hoses may be subjected to high pressures, T-bolt clamps feature a T-shaped bolt that provides additional clamping force and stability.

Applications of GM Hose Clamps

In GM vehicles, hose clamps are used in numerous systems, including coolant, fuel, and air intake systems. Each application demands different levels of clamping pressure and resistance to environmental conditions, such as temperature fluctuations and exposure to chemicals. For instance, in cooling systems, hose clamps must withstand high temperatures and pressures without failing, whereas in fuel systems, they must resist corrosion caused by fuel additives.

Moreover, the design and materials used in GM hose clamps ensure compatibility with various environmental conditions. Many clamps are engineered with stainless steel or high-grade plastic to resist rust and corrosion, ensuring longevity and reliability.

Maintenance and Replacement

While GM hose clamps are designed for durability, they can wear out over time due to vibration, exposure to extreme temperatures, and aging materials. Regular inspection of hose clamps is essential to prevent leaks and ensure optimal vehicle performance. Signs that a hose clamp may need replacement include visible rust, cracks in the clamp, or signs of fluid leakage around the hose.

In conclusion, GM hose clamps are a crucial element in the functioning of automotive systems. Understanding their types, applications, and the importance of regular maintenance can help vehicle owners and mechanics ensure reliability and efficiency. By prioritizing quality components like GM hose clamps, one can significantly reduce the risk of leaks and mechanical issues, thereby enhancing the overall performance and safety of the vehicle.

-

German Style Hose Clamp Manufacturer Quick Lock Worm Gear Hose Clamp Supplier

NewsJul.04,2025

-

Steel Midsole with Stainless Steel – Durable, Lightweight Safety Solutions from Top Factories and Suppliers

NewsJun.24,2025

-

High-Quality Stainless Steel Midsoles in EN Standard – Reliable Factories & Suppliers

NewsJun.10,2025

-

High-Quality Steel Midsole Stainless Steel Factory & Suppliers Durable Safety Solutions

NewsJun.10,2025

-

Steel Plate Midsole Durable Support for Footwear Applications

NewsJun.10,2025

-

Top Tube Clamp Manufacturers Durable Pipe & Hose Solutions

NewsJun.10,2025