- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

des . 15, 2024 14:21 Back to list

rolled edge hose clamps manufacturer

The Importance of Rolled Edge Hose Clamps A Comprehensive Guide

In the world of plumbing, automotive, and industrial applications, ensuring a secure and leak-free connection is paramount. One crucial component that aids in achieving this is the hose clamp, particularly the rolled edge hose clamp. In this article, we will explore the benefits of rolled edge hose clamps, the manufacturing process, and why choosing a reliable manufacturer is essential.

Understanding Rolled Edge Hose Clamps

Rolled edge hose clamps are widely recognized for their unique edge design, which provides several advantages over standard hose clamps. The rolled edge feature enhances the overall strength of the clamp, reducing the risk of damage to the hose being secured. This design helps distribute clamping force evenly across the hose surface, minimizing the potential for leaks and ensuring a strong grip.

Advantages of Rolled Edge Hose Clamps

1. Enhanced Durability The rolled edges of the clamp provide added strength and resistance to deformation. This is especially important in high-pressure applications where traditional clamps may fail.

2. Reduced Hose Damage The smooth, rounded edges of rolled edge hose clamps minimize the risk of cutting or pinching the hose material. This is critical for maintaining the integrity of the hose, especially in applications involving flexible tubing or vulnerable materials.

3. Improved Sealing The design of rolled edge clamps allows for a more uniform distribution of pressure around the circumference of the hose. This results in a superior seal, reducing the chances of leaks and enhancing overall performance.

4. Versatile Applications Rolled edge hose clamps can be used across various industries, including automotive, manufacturing, and construction. Their ability to adapt to different hose materials and sizes makes them a popular choice for many applications.

The Manufacturing Process

The production of rolled edge hose clamps typically involves several key steps. The primary materials used are stainless steel and other corrosion-resistant alloys. The manufacturing process begins with cutting the steel into strips, which are then shaped and rolled to create the edge.

rolled edge hose clamps manufacturer

Following this, the clamps undergo a heat treatment process to enhance their strength and durability. Quality control measures are implemented at each stage to ensure that the final product meets industry standards and specifications. This thorough manufacturing process underscores the importance of partnering with a reputable rolled edge hose clamp manufacturer.

Choosing the Right Manufacturer

When it comes to selecting a rolled edge hose clamp manufacturer, several factors should be considered

1. Experience and Expertise Choose a manufacturer with a proven track record in producing high-quality hose clamps. An established company is likely to have the expertise needed to deliver reliable products.

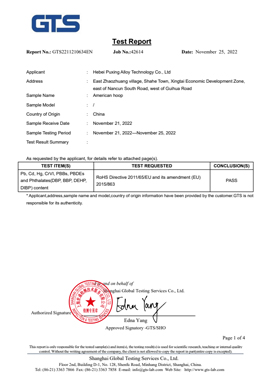

2. Quality Assurance Ensure that the manufacturer adheres to strict quality control measures. Certifications such as ISO 9001 can be a good indicator of a company's commitment to quality.

3. Customization Options Depending on your specific needs, you may require customized clamps. A good manufacturer should be able to accommodate custom sizes, materials, and designs.

4. Customer Reviews and Testimonials Research reviews and testimonials from previous customers. Their experiences can provide valuable insights into the manufacturer's reliability and customer service.

5. Support and Service A reputable manufacturer should also offer comprehensive customer support, including technical assistance and after-sales service.

Conclusion

In conclusion, rolled edge hose clamps are essential components in various applications that require reliable sealing and security. Their unique design offers numerous advantages, including enhanced durability, reduced hose damage, and improved sealing capabilities. Selecting a skilled and trustworthy manufacturer is crucial for ensuring the production of high-quality hose clamps that meet your needs. By choosing wisely, you can ensure the success of your projects and the longevity of the connections you are securing.

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025