- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

sep . 04, 2024 16:20 Back to list

2 t bolt hose clamp factories

Understanding 2% T Bolt Hose Clamp Factories

In the realm of industrial manufacturing, hose clamps play a pivotal role in ensuring secure connections in various applications, ranging from automotive systems to plumbing and beyond. Among the different types of hose clamps available in the market, the T bolt hose clamp has carved a niche for itself due to its robust design and efficient performance. This article delves into the significance of 2% T bolt hose clamp factories in the manufacturing landscape.

What Are T Bolt Hose Clamps?

T bolt hose clamps are heavy-duty clamps designed to provide a secure grip around hoses, ensuring they remain tightly fastened under pressure. The design incorporates a T-shaped bolt that enables even distribution of clamping force, making it an ideal choice for high-performance applications. These clamps are particularly favored in environments where hoses must withstand extreme temperatures, pressures, and vibrations, such as in automotive and industrial machinery.

The Role of 2% T Bolt Hose Clamp Factories

The designation “2% T bolt hose clamp factories” refers to specialized manufacturing facilities that produce T bolt hose clamps with a focus on quality and efficiency. These factories typically adhere to stringent manufacturing standards and employ advanced technology to create durable and reliable products. The term “2%” may indicate a specific quality metric, efficiency rate, or target market, emphasizing a commitment to excellence.

Manufacturing Process

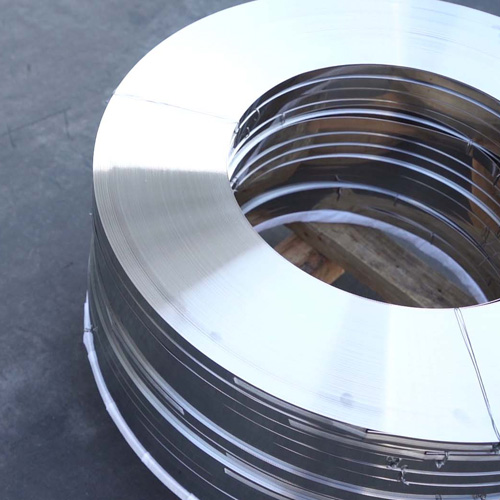

The manufacturing process in these factories involves several critical steps to ensure the clamps meet industry standards. Initially, raw materials, typically stainless steel or coated metals, are sourced. The selection of high-quality materials is crucial, as they significantly affect the durability and corrosion resistance of the clamps.

2 t bolt hose clamp factories

Once materials are procured, they undergo cutting, bending, and shaping through automated machinery. Precision is vital in these processes to ensure that each clamp fits snugly and performs efficiently under pressure. The clamps are then assembled with the T-bolt, which is often complemented by a nut and washer for enhanced stability.

Quality control is an integral aspect of the manufacturing process. After production, each clamp undergoes rigorous testing to assess its strength, elasticity, and overall performance. Factories may perform pressure tests and corrosion resistance assessments to guarantee that the final products can meet the demands of various applications.

Market Demand and Applications

The demand for T bolt hose clamps has seen a steady increase, driven by growth in sectors such as automotive, aerospace, and industrial manufacturing. As machinery and technology evolve, the need for reliable fastening solutions like T bolt clamps has become paramount.

Additionally, with the rise of eco-friendly initiatives, many manufacturers are exploring sustainable materials and processes, making T bolt hose clamps increasingly appealing to environmentally conscious consumers and businesses.

Conclusion

In summary, 2% T bolt hose clamp factories play an essential role in the manufacturing landscape by producing high-quality, reliable clamps that cater to a range of industrial applications. With a focus on precise manufacturing processes and stringent quality control measures, these factories contribute significantly to the safety and efficiency of machinery and systems that rely on secure hose connections. As industries continue to evolve, the importance of such specialized manufacturing facilities will only grow, ensuring that they remain integral to the supply chain of high-performance components.

-

High Quality Precision Stainless Steel Strip - GPT-4-Turbo Grade

NewsAug.02,2025

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, High Torque

NewsJul.31,2025