- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

lis . 07, 2024 14:17 Back to list

hose clamps stainless steel factory

The Importance of Quality in Stainless Steel Hose Clamps A Look into Manufacturing Practices

In the world of industrial manufacturing, attention to detail and quality control is paramount, especially for products like stainless steel hose clamps. These clamps are essential for securing hoses tightly over fittings, preventing leaks, and ensuring efficient operation in various applications ranging from automotive to plumbing. In this article, we will explore the importance of stainless steel hose clamps, while delving into the manufacturing practices that set quality factories apart.

The Importance of Quality in Stainless Steel Hose Clamps A Look into Manufacturing Practices

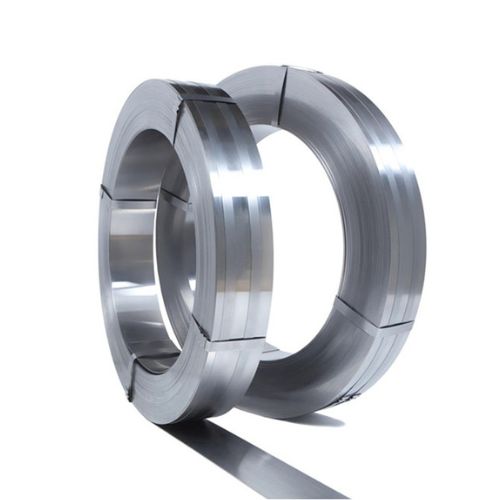

A reputable stainless steel hose clamp factory employs advanced manufacturing techniques to produce reliable products. Initially, high-grade stainless steel is sourced, with alloys like 304 and 316 being the most common because of their strong corrosion resistance properties. The choice of material is the foundation upon which quality is built. After material selection, the manufacturing process involves several key steps including cutting, shaping, and welding.

hose clamps stainless steel factory

Precision cutting machines are used to ensure that each strip of stainless steel is cut to the exact required length. Manual errors can introduce inconsistencies; thus, automation in this process significantly enhances accuracy. Following cutting, the clamps are shaped using specialized bending machines which form the material into a circular clamp. The importance of this step cannot be overstated, as it must be executed with precision to ensure the integrity of the clamp when installed.

Welding is another critical stage in the production of stainless steel hose clamps. Factories with certified welders utilize advanced techniques such as TIG (Tungsten Inert Gas) welding to create robust joints that can withstand high pressure and extreme conditions. This process ensures that there are no weak points in the assembly of the clamp, which could lead to failures under stress. Quality control measures, such as non-destructive testing, are employed to inspect welds for any defects.

Post-manufacturing, the clamps undergo rigorous testing procedures. This may include tensile strength tests, torque tests, and environmental exposure tests to ensure they meet industry standards. A factory that prioritizes quality will not only adhere to these testing protocols but also maintain comprehensive records of results, allowing for traceability and accountability in their production process.

In conclusion, the production of stainless steel hose clamps is no simple task. It requires a perfect blend of quality raw materials, advanced manufacturing techniques, and stringent testing protocols. For industries where reliability is non-negotiable, choosing a factory that prioritizes quality in its hose clamp production is imperative. By ensuring that these crucial components are manufactured to the highest standards, companies can safeguard their operations and foster trust with their clients. Quality should never be an afterthought; it is a commitment that begins at the very first stage of production.

-

German Style Hose Clamp Manufacturer Quick Lock Worm Gear Hose Clamp Supplier

NewsJul.04,2025

-

Steel Midsole with Stainless Steel – Durable, Lightweight Safety Solutions from Top Factories and Suppliers

NewsJun.24,2025

-

High-Quality Stainless Steel Midsoles in EN Standard – Reliable Factories & Suppliers

NewsJun.10,2025

-

High-Quality Steel Midsole Stainless Steel Factory & Suppliers Durable Safety Solutions

NewsJun.10,2025

-

Steel Plate Midsole Durable Support for Footwear Applications

NewsJun.10,2025

-

Top Tube Clamp Manufacturers Durable Pipe & Hose Solutions

NewsJun.10,2025