- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 03, 2024 17:45 Back to list

7/8 hose clamp manufacturers

The Importance of 7/8 Inch Hose Clamps in Manufacturing

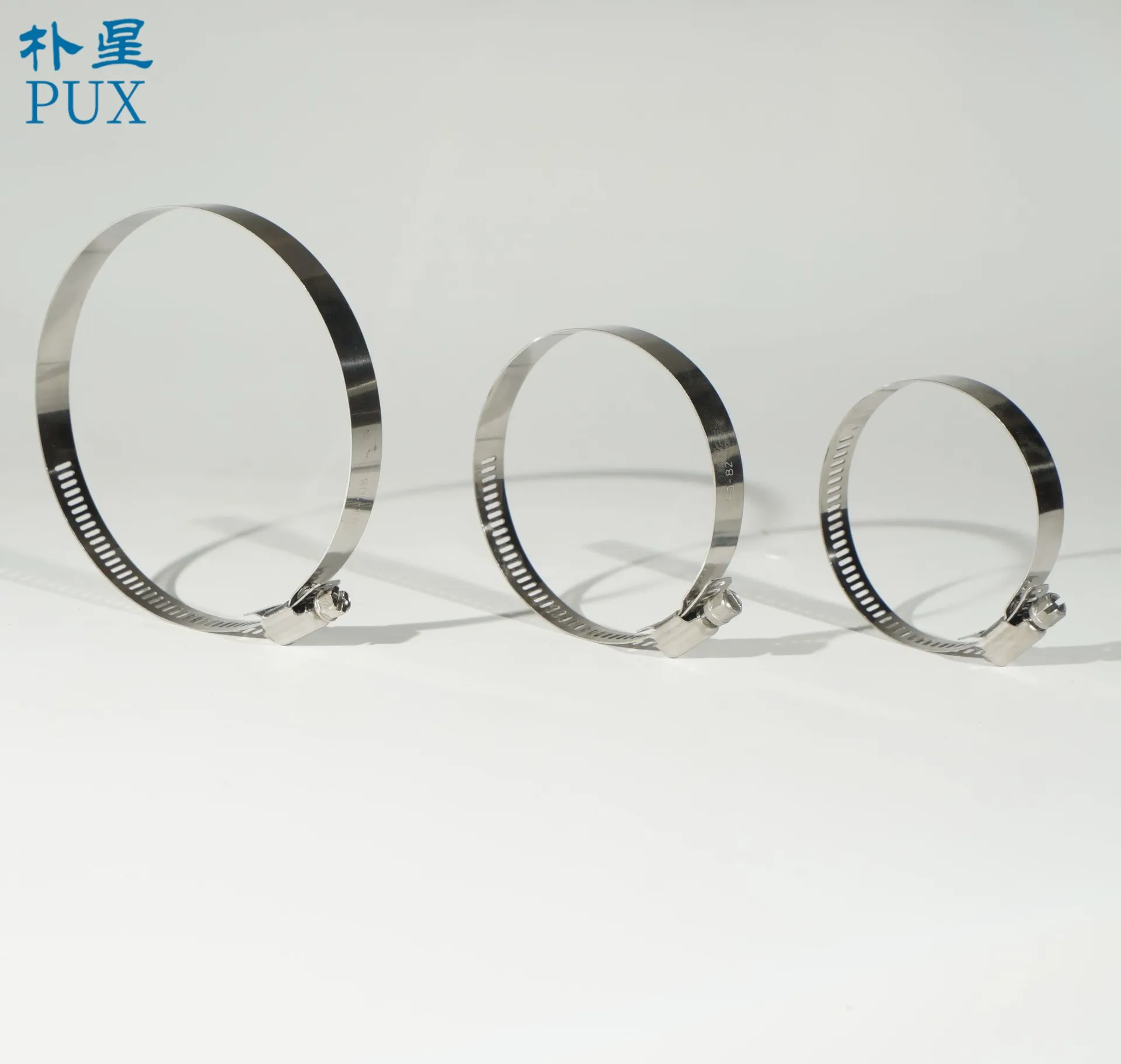

Hose clamps are essential components used in various industries, including automotive, plumbing, and agricultural sectors. Among the many sizes available, the 7/8 inch hose clamp stands out due to its versatility and robust design that meets the demands of different applications. In this article, we will explore the significance of 7/8 inch hose clamps, their manufacturing process, and the leading manufacturers in the industry.

What are Hose Clamps?

Hose clamps, also known as hose clips, are devices used to secure hoses to fittings, preventing the leakage of fluids or gases. They provide a reliable means of achieving a tight seal and are crucial in systems where high pressure is present. The 7/8 inch size is commonly used in applications such as fuel lines, cooling systems, and various industrial setups.

Importance of 7/8 Inch Hose Clamps

The 7/8 inch hose clamp is favored in many applications due to its ability to accommodate a range of hose diameters while providing a secure hold. The size is particularly suitable for automotive hoses, electrical conduit systems, and irrigation systems in agriculture. A well-fitted hose clamp ensures minimal leakage, which can lead to significant savings in maintenance costs and resource conservation.

Moreover, the importance of hose clamps extends beyond simple fastening. They are integral to safety, as a loose or failing clamp can result in leaks that may lead to hazardous situations, especially in the automotive and industrial sectors. Therefore, the reliability of 7/8 inch hose clamps plays a crucial role in preventing accidents and failures in equipment.

Manufacturing Process

The manufacturing of hose clamps, including the 7/8 inch variety, involves several steps. The key materials used in production include stainless steel, carbon steel, and plastic. Stainless steel is often preferred due to its resistance to corrosion and durability, making it suitable for both indoor and outdoor applications.

1. Material Selection The choice of material is critical, with stainless steel being a popular option for its strength and weather resistance.

2. Cutting and Shaping The selected materials are cut to the desired length and shaped into the clamp’s form. This process often involves bending and forming the metal to create the necessary holding capacity.

7/8 hose clamp manufacturers

3. Coating and Finishing To enhance the durability and corrosion resistance of hose clamps, a coating process may be applied. This step helps in prolonging the life of the clamp when exposed to various environmental conditions.

4. Quality Control After production, each clamp goes through rigorous quality control checks. This ensures that they meet industry standards and can perform effectively under pressure.

5. Packaging and Distribution Once passed through quality assurance, the hose clamps are packaged and prepared for distribution to wholesalers and retailers.

Leading Manufacturers

Several companies have established themselves as leaders in the manufacturing of hose clamps, including 7/8 inch varieties. Notable manufacturers include

- Oetiker Renowned for producing high-quality clamps with a focus on innovation and advanced manufacturing techniques. - Ideal Clamp Products Offers a wide range of hose clamps, emphasizing durability and effectiveness in securing hoses.

- Würth Group A global provider that supplies a variety of fastening products, including hose clamps tailored for different industries.

These manufacturers contribute to the market by providing reliable, efficient, and high-quality products that meet the needs of various applications. They invest in research and development to innovate new designs that enhance performance and ease of use.

Conclusion

In summary, 7/8 inch hose clamps are vital components in numerous applications across different sectors. Their role in ensuring a secure fit, preventing leaks, and enhancing safety cannot be overstated. The manufacturing process involves careful material selection, precision engineering, and stringent quality control to produce reliable hose clamps. With reputable manufacturers leading the way, industries can trust in the performance of 7/8 inch hose clamps to safeguard their systems and operations. As demand continues to grow, the importance of these simple yet critical devices will remain ever-present.

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025