- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Oct . 10, 2024 20:11 Back to list

Bandit Hose Clamps Manufacturing Facilities Overview and Key Insights

The Evolution and Significance of Bandit Hose Clamps in Industrial Manufacturing

In the realm of industrial manufacturing, the role of hose clamps is often underestimated. Among these essential components, Bandit hose clamps stand out due to their robust design, versatility, and critical application in various sectors. These clamps, commonly used to secure hoses in a multitude of setups, have undergone significant evolution in design and manufacturing, driven by the ever-growing demands of industries such as automotive, aerospace, agriculture, and construction.

Understanding Hose Clamps

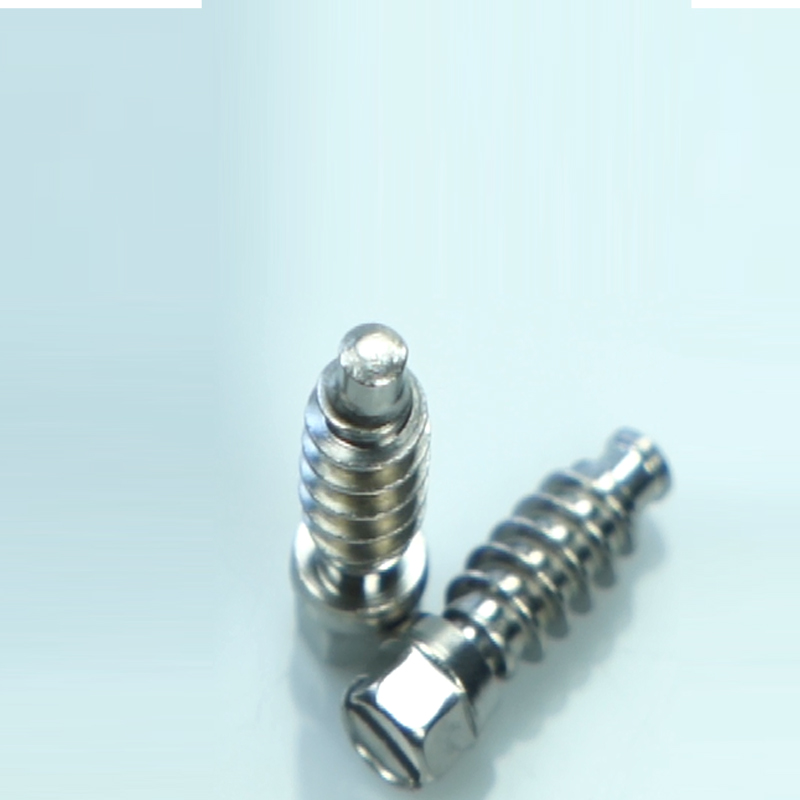

Hose clamps are mechanical fasteners that provide a secure connection by enclosing a hose onto a fitting. The primary purpose of these clamps is to prevent fluid leaks by maintaining a tight grip around the hose. While there are various types of hose clamps—including worm gear clamps, spring clamps, and T-bolt clamps—Bandit hose clamps are distinguished by their unique design and enhanced reliability.

Key Features of Bandit Hose Clamps

1. Superior Material Quality Bandit hose clamps are typically made from high-quality materials like stainless steel and zinc-coated steel. This not only ensures durability but also resistance to corrosion, making them suitable for both indoor and outdoor applications.

2. Versatile Applications Whether in automotive coolant systems, fuel lines, or industrial machinery, Bandit hose clamps are designed to accommodate a wide range of hose sizes and types. This versatility enhances their usability across different industries, allowing manufacturers to streamline their operations.

3. Innovative Design The design of Bandit hose clamps emphasizes efficiency and performance. Many clamps feature unique tightening mechanisms that provide even pressure distribution, preventing hose damage while ensuring a secure fit.

4. Ease of Installation and Maintenance Bandit hose clamps are engineered for quick installation and removal, which significantly reduces labor costs and downtime during maintenance operations. This ease of use is attractive to industries where time efficiency is critical.

bandit hose clamps factories

The Manufacturing Process

The manufacturing of Bandit hose clamps involves several meticulous steps to ensure quality and performance. Initially, raw materials are selected based on their properties to meet specific industry standards. After the material selection, the design phase incorporates advanced engineering techniques to create prototypes that can withstand rigorous testing.

Once a prototype passes the necessary evaluations, mass production begins. This phase utilizes automated machinery coupled with skilled labor to produce high-precision hose clamps. Quality assurance protocols are integral throughout the manufacturing process to ensure that each clamp meets the desired specifications and performance criteria.

Additionally, environmental considerations are becoming increasingly essential in manufacturing practices. Many factories producing Bandit hose clamps are implementing sustainable practices, such as efficient waste management systems and energy-efficient production techniques. This shift not only minimizes the environmental impact but also enhances the overall sustainability of the manufacturing process.

Trends in the Hose Clamp Market

The global market for hose clamps is witnessing several trends that indicate growth and evolution. As industries push for increased efficiency and reliability, there is a rising demand for high-performance hose clamps like those produced by Bandit. Furthermore, advancements in materials science are leading to the development of clamps that offer better heat and chemical resistance, broadening their applicability.

Alongside technological advancements, the integration of smart manufacturing principles is reshaping the landscape. Factories are adopting Industry 4.0 technologies, incorporating IoT devices and data analytics to monitor production processes in real time. This transformation not only enhances quality control but also allows manufacturers to respond rapidly to market changes.

Conclusion

In conclusion, Bandit hose clamps are more than just simple fasteners; they are a critical component of modern industrial manufacturing. Their evolution reflects the constant demand for innovation and reliability across various sectors. As manufacturers continue to focus on sustainability and efficiency, the importance of high-quality hose clamps will only grow. Embracing these advancements equips industries to meet future challenges while ensuring safety and performance in their operations. As the bandit hose clamp industry continues to evolve, its contribution to the complex machinery that drives our world cannot be overstated.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025