- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

tammi . 14, 2025 10:58 Back to list

stainless steel hose clip

In the world of hardware and plumbing, the importance of selecting the right 1/4 hose clamps cannot be overstated. These seemingly insignificant components play a pivotal role in ensuring secure and leak-free connections, which are vital for both domestic and industrial applications. This article delves into the nuanced aspects of choosing and utilizing 1/4 hose clamps, drawing from authentic experiences and expert insights to offer a comprehensive guide that is authoritative and trustworthy.

Furthermore, it is essential to consider the type of clamp. Worm drive clamps are ideal for a wide range of pressure requirements and are adjustable to a variety of diameter sizes, making them popular for general use. For high-pressure environments, such as turbocharged automotive systems, T-bolt clamps are recommended due to their robust construction and higher clamping force. Reliability is not just about the initial installation but also about maintenance. Regular inspections can help detect wear and prevent leaks before they become problematic. Trustworthiness in performance arises when hose clamps are periodically checked and replaced as needed, following the manufacturer’s guidelines for lifespan and wear. The proper sourcing of hose clamps cannot be ignored when discussing expertise. Opting for products from reputable manufacturers who provide detailed product specifications and warranties can ensure quality and peace of mind. Certifications, such as those from ISO or ASTM, serve as a benchmark for quality and reliability. In summary, 1/4 hose clamps, though small, are a critical component in any system requiring secured lines or tubing. Their effectiveness is rooted in careful selection, precise installation, and regular maintenance. Understanding these elements not only results in efficient and safe operations but also reinforces the responsibility of making informed choices based on expertise and trustworthiness. Whether for professional or home use, an investment in quality hose clamps is an investment in peace of mind and operational success.

Furthermore, it is essential to consider the type of clamp. Worm drive clamps are ideal for a wide range of pressure requirements and are adjustable to a variety of diameter sizes, making them popular for general use. For high-pressure environments, such as turbocharged automotive systems, T-bolt clamps are recommended due to their robust construction and higher clamping force. Reliability is not just about the initial installation but also about maintenance. Regular inspections can help detect wear and prevent leaks before they become problematic. Trustworthiness in performance arises when hose clamps are periodically checked and replaced as needed, following the manufacturer’s guidelines for lifespan and wear. The proper sourcing of hose clamps cannot be ignored when discussing expertise. Opting for products from reputable manufacturers who provide detailed product specifications and warranties can ensure quality and peace of mind. Certifications, such as those from ISO or ASTM, serve as a benchmark for quality and reliability. In summary, 1/4 hose clamps, though small, are a critical component in any system requiring secured lines or tubing. Their effectiveness is rooted in careful selection, precise installation, and regular maintenance. Understanding these elements not only results in efficient and safe operations but also reinforces the responsibility of making informed choices based on expertise and trustworthiness. Whether for professional or home use, an investment in quality hose clamps is an investment in peace of mind and operational success.

Share

Next:

Latest news

-

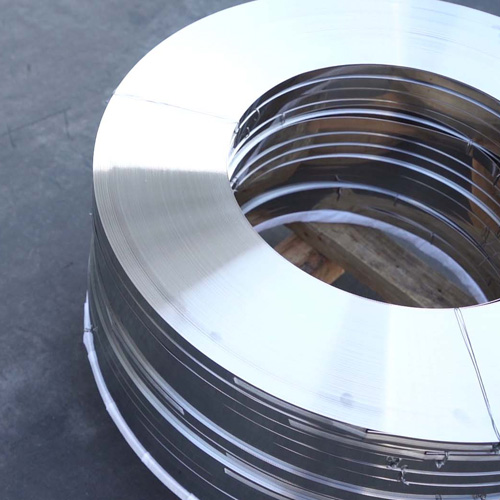

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025