- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

aug. . 13, 2024 08:36 Back to list

A Comprehensive Guide to Spring Hose Clamp Manufacturers and Their Production Processes

The Importance of Spring Hose Clamps in Industrial Applications

In the world of industrial manufacturing and mechanical engineering, the importance of reliable fastening solutions can't be overstated. Among these solutions, spring hose clamps play a pivotal role in ensuring the secure attachment of hoses to various fittings, ultimately contributing to the overall efficiency and safety of mechanical systems. This article delves into the significance of spring hose clamp factories, their manufacturing processes, and their impact on various industries.

Understanding Spring Hose Clamps

Spring hose clamps are specialized fastening devices designed to hold hoses onto fittings or connectors securely. Unlike traditional hose clamps that require manual tightening, spring hose clamps operate through a unique mechanism that provides constant pressure around the hose. This innovative design ensures a snug fit that can accommodate the natural expansion and contraction of the hose material due to temperature changes, vibrations, or pressure fluctuations.

Manufacturing Process

The production of spring hose clamps typically begins in dedicated factories equipped with advanced machinery and technology. The process involves several key steps

1. Material Selection High-quality materials, such as stainless steel and carbon steel, are chosen for their durability, resistance to corrosion, and ability to withstand extreme temperatures. The selection of material is crucial for the performance and longevity of the clamps.

2. Precision Engineering Factories utilize Computer Numerical Control (CNC) machines to cut and shape the materials with high precision. This ensures that each clamp meets the exact specifications required for various applications.

3. Spring Mechanism Creation The heart of the spring hose clamp is its spring mechanism, which requires careful engineering. Factories employ skilled technicians to manufacture the spring component, ensuring that it delivers the correct amount of tension and flexibility.

1 4 spring hose clamp factories

4. Assembly Once the individual components are produced, they are assembled in a controlled environment to maintain quality standards. Quality control checks are performed at every stage to ensure that each clamp will function correctly in its intended application.

5. Finishing Touches After assembly, clamps undergo finishing processes such as surface treatment and coating to enhance their corrosion resistance and aesthetic appeal. This step is crucial for applications in harsh environments.

Applications across Industries

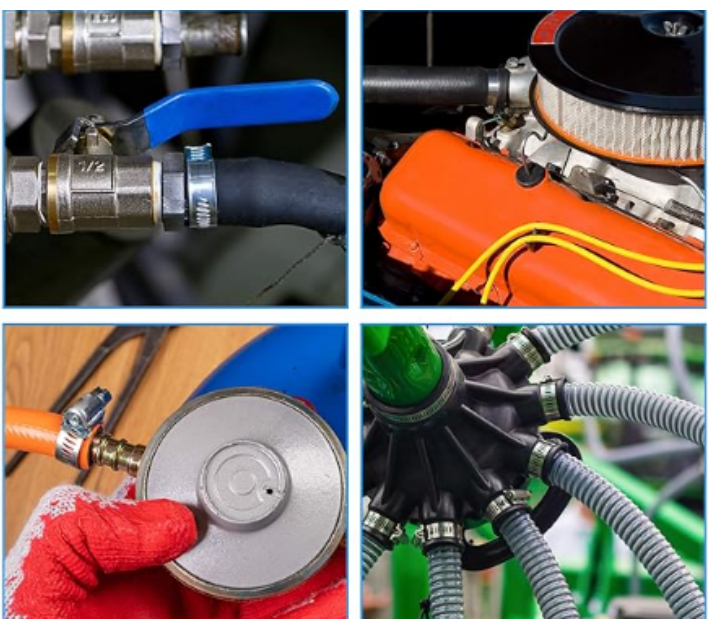

Spring hose clamps are widely used across various sectors, including automotive, aerospace, plumbing, and manufacturing. In the automotive industry, for instance, these clamps secure hoses that transport fluids such as coolant, fuel, and oil, ensuring that vehicles operate smoothly and safely. In aerospace applications, the reliability of hose clamps is vital, as even minor failures can lead to catastrophic consequences.

Moreover, in plumbing, spring hose clamps are commonly used to connect hoses to faucets, pumps, and other fixtures. Their ability to maintain a tight seal under varying conditions makes them an indispensable tool for plumbers and contractors.

Conclusion

The role of spring hose clamp factories extends far beyond mere manufacturing. They are integral to the supply chain that supports the safe and efficient operation of various mechanical systems. By producing high-quality, reliable clamps, these factories contribute to the progress of industries that demand precision and durability.

As technology advances and industries evolve, the demand for innovative fastening solutions like spring hose clamps is expected to grow. With an increasing focus on safety, efficiency, and sustainability, the role of these clamps in manufacturing and engineering will remain vital for the foreseeable future. In summary, spring hose clamp factories not only produce essential components but also ensure the functionality and integrity of systems that power our modern world.

-

High-Quality Stainless Steel Midsoles in EN Standard – Reliable Factories & Suppliers

NewsJun.10,2025

-

High-Quality Steel Midsole Stainless Steel Factory & Suppliers Durable Safety Solutions

NewsJun.10,2025

-

Steel Plate Midsole Durable Support for Footwear Applications

NewsJun.10,2025

-

Top Tube Clamp Manufacturers Durable Pipe & Hose Solutions

NewsJun.10,2025

-

Durable T Bolt Hose Clips Secure Leak-Proof Design

NewsJun.09,2025

-

Easy-Install Adjustable Pipe Tube Clamps Durable Construction

NewsJun.09,2025