- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

feb . 12, 2025 18:04 Back to list

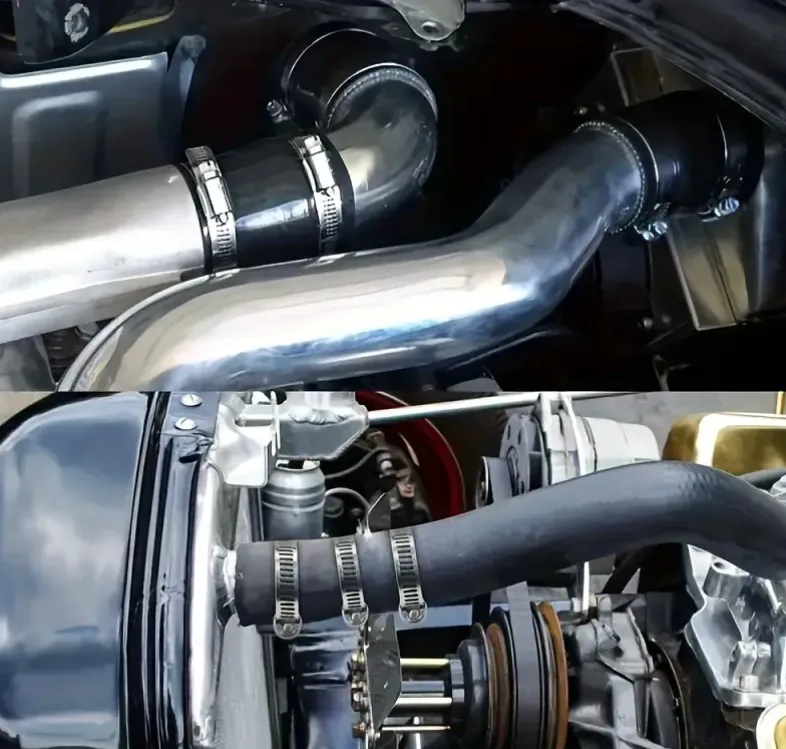

discharge hose clamp

Selecting the right discharge hose clamp is imperative for ensuring efficiency and safety in various industrial and residential applications. A discharge hose clamp, though seemingly small, plays a pivotal role in maintaining the integrity of hose assemblies. In this comprehensive guide, we delve into everything you need to know about discharge hose clamps, drawing on expert insights and real-life experiences to highlight the essence of these components.

Beyond material and size, the type of discharge hose clamp can affect its performance in different settings. T-bolt clamps, for instance, provide high strength and reliability, making them preferable for high-pressure applications. On the other hand, worm gear clamps are often favored for their versatility and ease of installation. A veteran field engineer recounted a situation where the use of a T-bolt clamp was instrumental in sustaining pressure in an automotive cooling system, thereby preventing costly downtime. Moreover, the technological advancements in discharge hose clamps today introduce innovative designs that offer enhanced functionality. For instance, some modern clamps come with quick-release mechanisms that facilitate maintenance and repairs, an asset highly valued in fast-paced environments. A plant supervisor highlighted the time-saving benefits of these advanced clamps, stating they reduced repair downtime by nearly 50% in their production facility. Trustworthiness in the choice of discharge hose clamps is often validated through adherence to industry standards and certifications. Many reputable manufacturers ensure their products meet rigorous standards, such as those set by the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). Relying on certified products can assure users of the performance and safety of the hose clamps. In fact, consulting with a manufacturer representative or a certified supply chain expert can provide guidance tailored to specific industrial needs. In conclusion, the selection of a discharge hose clamp is not merely a cursory task but a critical decision that influences the operational efficiency and safety of fluid systems. Leveraging expertise, focusing on material and size, considering type-specific applications, and choosing certified products are all practices that underpin the selection process. By incorporating firsthand experiences and specialized knowledge, one can make informed decisions that elevate the effectiveness and reliability of hose assemblies, ultimately leading to reduced maintenance costs and enhanced operational performance.

Beyond material and size, the type of discharge hose clamp can affect its performance in different settings. T-bolt clamps, for instance, provide high strength and reliability, making them preferable for high-pressure applications. On the other hand, worm gear clamps are often favored for their versatility and ease of installation. A veteran field engineer recounted a situation where the use of a T-bolt clamp was instrumental in sustaining pressure in an automotive cooling system, thereby preventing costly downtime. Moreover, the technological advancements in discharge hose clamps today introduce innovative designs that offer enhanced functionality. For instance, some modern clamps come with quick-release mechanisms that facilitate maintenance and repairs, an asset highly valued in fast-paced environments. A plant supervisor highlighted the time-saving benefits of these advanced clamps, stating they reduced repair downtime by nearly 50% in their production facility. Trustworthiness in the choice of discharge hose clamps is often validated through adherence to industry standards and certifications. Many reputable manufacturers ensure their products meet rigorous standards, such as those set by the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). Relying on certified products can assure users of the performance and safety of the hose clamps. In fact, consulting with a manufacturer representative or a certified supply chain expert can provide guidance tailored to specific industrial needs. In conclusion, the selection of a discharge hose clamp is not merely a cursory task but a critical decision that influences the operational efficiency and safety of fluid systems. Leveraging expertise, focusing on material and size, considering type-specific applications, and choosing certified products are all practices that underpin the selection process. By incorporating firsthand experiences and specialized knowledge, one can make informed decisions that elevate the effectiveness and reliability of hose assemblies, ultimately leading to reduced maintenance costs and enhanced operational performance.

Share

Latest news

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025

-

High-Quality T Bolt Hose Clip from Leading Factory & Suppliers Reliable t bolt hose clip Factories

NewsJul.07,2025

-

Mini Hose Clamp Manufacturer & Supplier Precision Hose Clamps Mini Clamp Factory

NewsJul.07,2025