- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 10, 2024 08:49 Back to list

cold rolled steel strip

Understanding Cold Rolled Steel Strip Properties, Applications, and Advantages

Cold rolled steel strips are widely recognized for their exceptional qualities and versatility in a myriad of applications. Unlike hot rolled steel, which is processed at high temperatures, cold rolled steel undergoes deformation at room temperature. This method not only enhances its mechanical properties but also provides a smooth and polished surface finish that is particularly appealing for various industrial uses.

Properties of Cold Rolled Steel Strip

One of the most notable properties of cold rolled steel strips is their impressive strength. The cold rolling process enhances the tensile strength and hardness of the steel, making it suitable for applications that require superior performance. This increased strength comes from strain hardening, which occurs as the steel is forced through rolls. Cold rolled steel typically exhibits tighter tolerances, meaning it has a consistent thickness and shape, which is crucial for precision engineering components.

In addition to strength, cold rolled steel strips have excellent dimensional stability. This property ensures that the material maintains its shape and size even under stress, making it ideal for parts that need to fit together accurately. The smooth surface finish not only enhances its aesthetic appeal but also improves its corrosion resistance when coated or galvanized.

Applications of Cold Rolled Steel Strip

The versatility of cold rolled steel strips allows for a wide range of applications across multiple industries. One significant area of use is in the automotive industry, where high-strength steel strips are employed in the manufacturing of body panels, frames, and structural components. The strength and formability of cold rolled steel make it an excellent choice for automotive parts that must endure significant stress and impact.

Another primary application is in the production of appliances. Cold rolled steel strips are commonly used in making refrigerator cabinets, washing machines, and other household appliances due to their durability and appealing finish. Furthermore, they play a critical role in the construction industry, being utilized in architectural elements, roofing materials, and structural components.

cold rolled steel strip

The electrical industry also finds cold rolled steel strips valuable, particularly for making electrical enclosures and components. The material’s ability to be easily formed and its excellent electrical conductivity make it suitable for a variety of electronic applications. Additionally, cold rolled steel strips are increasingly used in the manufacturing of precision tools and components due to their enhanced performance characteristics.

Advantages of Cold Rolled Steel Strips

The advantages of using cold rolled steel strips are manifold. Firstly, their superior mechanical properties provide enhanced durability, making them a preferred choice in demanding applications. The tighter tolerances and superior surface finish reduce the need for additional machining, thereby saving time and costs in production processes.

Moreover, cold rolled steel strips are highly adaptable to various coatings, such as galvanization and painting, which significantly improve their corrosion resistance. This aspect is essential for products exposed to harsh environments, ensuring longevity and reliability.

Cold rolled steel strips are also more eco-friendly than their hot rolled counterparts. The cold rolling process requires less energy and induces fewer emissions, aligning with modern sustainability goals. As industries continue to seek more sustainable practices, the demand for cold rolled steel is likely to rise.

Conclusion

In conclusion, cold rolled steel strips play an indispensable role in various industries, thanks to their enhanced strength, dimensional precision, and aesthetic appeal. Their versatility makes them suitable for numerous applications, from automotive parts to household appliances and electrical components. With continuous advancements in steel processing technologies, the future of cold rolled steel strips looks promising, providing solutions to meet the evolving needs of modern manufacturing. As industries strive for efficiency and sustainability, the adoption of cold rolled steel will only increase, underpinning its significance in the global market.

-

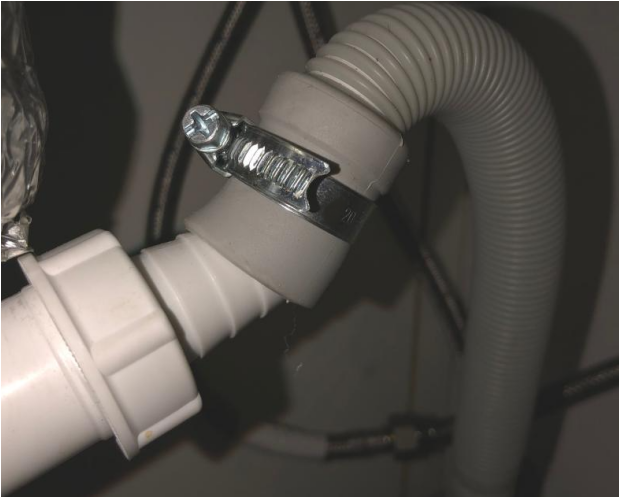

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.12,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.12,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.12,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.12,2025

-

Precision Stainless Steel Strip Roll & Coil Manufacturer

NewsAug.12,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.11,2025