- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dis . 26, 2024 14:00 Back to list

Galvanized Iron Hollow Bolts and Hose Clamps Manufacturing Facilities and Production Insights

Understanding the Production and Importance of Galvanized Iron Hollow Bolt Hose Clamps

In the realm of industrial hardware, galvanized iron hollow bolt hose clamps play a pivotal role in ensuring secure fittings and reliable connections. These clamps are especially significant in various applications ranging from automotive and engineering to plumbing and agricultural systems. This article delves into the significance, manufacturing processes, and applications of galvanized iron hollow bolt hose clamps, emphasizing the factories that produce these essential components.

What are Galvanized Iron Hollow Bolt Hose Clamps?

Galvanized iron hollow bolt hose clamps are fastening devices designed to connect and secure hoses, ensuring that they do not come loose under pressure or movement. The construction of these clamps typically includes a hollow bolt and a band that can be adjusted to fit various hose diameters, providing a tight and secure fit. The galvanization process involves coating the iron with zinc to prevent corrosion, thus enhancing the durability and lifespan of the clamps. This makes them especially ideal for applications where exposure to moisture and varying temperatures is a concern.

Manufacturing Processes

The production of galvanized iron hollow bolt hose clamps involves several key processes, typically executed in specialized factories. Firstly, the raw materials are sourced, which include high-quality iron and zinc for galvanization. The manufacturing process starts with the cutting of iron strips into the requisite sizes needed for the clamps. Following that, the pieces are shaped using pressing or molding techniques.

Next, the hollow bolts are created, ensuring they meet specific engineering standards for strength and functionality. Once the shaping is complete, the pieces undergo a galvanization process where they are submerged in molten zinc, creating a protective layer that inhibits rust and enhances durability. After galvanization, the components are inspected for quality assurance to ensure they meet industry standards. In factories, precision is paramount, and certain measurements and tolerances are meticulously adhered to in order to produce reliable products.

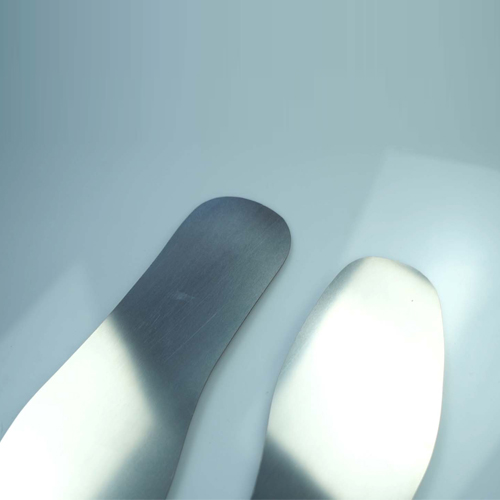

galvanized iron hollow bolt hose clamp factories

The Importance of Quality Control

Established factories prioritize quality control in their production lines. This is crucial not only for ensuring the effectiveness of the hose clamps but also for maintaining their reputation in the competitive market. Rigorous testing mechanisms are put in place, such as pressure testing and corrosion resistance checks, which help in verifying that each clamp can withstand its intended use. Any defect detected in the manufacturing process might lead to failures during application, which could result in significant operational issues for end-users.

Applications Across Industries

Galvanized iron hollow bolt hose clamps are utilized in a diverse array of sectors. In the automotive industry, they secure hoses related to fuel, coolant, and air intake systems, playing a critical role in engine performance. In plumbing, they are used to connect water hoses and pipes, preventing leaks that could lead to costly damage. Agricultural applications often see these clamps used in irrigation systems, ensuring consistent water flow while maintaining strong connections under varying pressure conditions.

Moreover, in HVAC systems, hose clamps are vital for securing ducts and tubing, contributing to the overall efficiency and effectiveness of heating and cooling systems. Their versatility across industries underscores the importance of reliable fastening solutions in everyday applications.

Conclusion

The production of galvanized iron hollow bolt hose clamps represents a vital segment of the industrial hardware market. With factories dedicated to high-quality manufacturing processes and stringent quality control measures, these components ensure safety and reliability in various applications. As industries continue to evolve and expand, the demand for durable and reliable hose clamps will remain significant, making their production an essential aspect of modern manufacturing. Understanding the role of these clamps in everyday applications can foster appreciation for the intricate processes and craftsmanship involved in their creation, highlighting the importance of sustainable and quality-driven production practices in the industry.

-

Hi-Grip Hose Clamps Heavy-Duty, Secure Sealing Solutions

NewsMay.22,2025

-

High-Quality Hose Clips Manufacturer Durable Brake & Fuel Spring Clamps

NewsMay.22,2025

-

Cold Rolled Stainless Steel Strip Suppliers & Factories High Precision & Durability

NewsMay.22,2025

-

Hi-Grip Hose Clamps Durable, Secure Vise Grip Solutions Suppliers

NewsMay.21,2025

-

Pipe Tube Hose Clips Durable Solutions from Trusted Factories & Suppliers

NewsMay.21,2025

-

High Torque Brake Hose Clips - Durable OEM/Aftermarket Solutions

NewsMay.21,2025