- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

feb . 19, 2025 02:49 Back to list

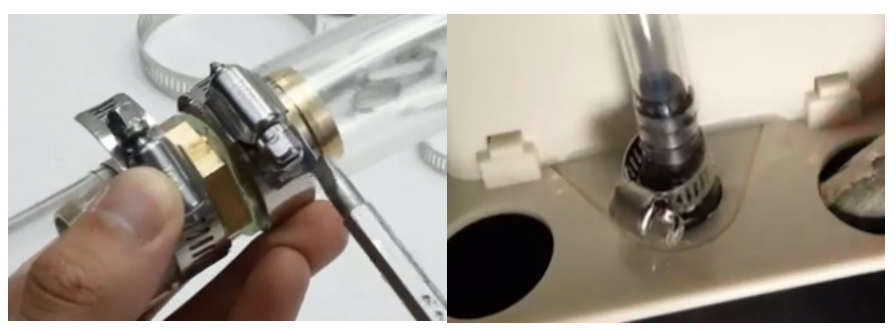

hose clamp heavy duty

Finding the right hose clamp for heavy-duty applications can often seem daunting. With various products available, making a choice involves understanding the nuances that distinguish a truly effective product from a generic one. This guide delves into the intricate landscape of heavy-duty hose clamps, offering insights derived from industry expertise and hands-on experience.

4. Ease of Installation and Maintenance In the field, efficiency is key. Hose clamps that feature a quick-release mechanism or easy-access tightening screws significantly reduce the time and effort needed for installation or adjustments. Accessibility and user-friendly designs, while often overlooked, contribute to the overall effectiveness of industrial operations. 5. Brand Reputation and Certifications Trusted manufacturers often offer certifications that testify to their product's compliance with international safety and quality standards. Engaging products from reputable brands not only provides peace of mind but also ensures that the clamps meet rigorous testing and quality assurance procedures. 6. Thermal and Pressure Capacity An often undervalued aspect, the clamp's ability to withstand extreme temperatures and pressures directly correlates with its application longevity. Heavy-duty hose clamps should be assessed for performance under expected temperature ranges and pressure levels pertinent to their intended use. Real-world applications showcase the versatility and necessity of high-quality heavy-duty hose clamps. In the automotive world, for example, these clamps ensure that critical fluid transport systems remain seamless, preventing leaks that could lead to overheating or engine failure. Similarly, in industrial machinery, these clamps must endure vibrations and pressure variations, maintaining consistent operations. To conclude, the selection of a heavy-duty hose clamp should be an informed decision, grounded in an understanding of the product’s technical attributes and performance capacity. Armed with expert knowledge and an appreciation for material science, industry professionals can optimize system integrity, enhancing both safety and efficiency. Users should visit product reviews, consult technical sheets, and even consider manufacturer support in navigating the multitude of options available, ensuring their choice aligns with their precise application needs.

4. Ease of Installation and Maintenance In the field, efficiency is key. Hose clamps that feature a quick-release mechanism or easy-access tightening screws significantly reduce the time and effort needed for installation or adjustments. Accessibility and user-friendly designs, while often overlooked, contribute to the overall effectiveness of industrial operations. 5. Brand Reputation and Certifications Trusted manufacturers often offer certifications that testify to their product's compliance with international safety and quality standards. Engaging products from reputable brands not only provides peace of mind but also ensures that the clamps meet rigorous testing and quality assurance procedures. 6. Thermal and Pressure Capacity An often undervalued aspect, the clamp's ability to withstand extreme temperatures and pressures directly correlates with its application longevity. Heavy-duty hose clamps should be assessed for performance under expected temperature ranges and pressure levels pertinent to their intended use. Real-world applications showcase the versatility and necessity of high-quality heavy-duty hose clamps. In the automotive world, for example, these clamps ensure that critical fluid transport systems remain seamless, preventing leaks that could lead to overheating or engine failure. Similarly, in industrial machinery, these clamps must endure vibrations and pressure variations, maintaining consistent operations. To conclude, the selection of a heavy-duty hose clamp should be an informed decision, grounded in an understanding of the product’s technical attributes and performance capacity. Armed with expert knowledge and an appreciation for material science, industry professionals can optimize system integrity, enhancing both safety and efficiency. Users should visit product reviews, consult technical sheets, and even consider manufacturer support in navigating the multitude of options available, ensuring their choice aligns with their precise application needs.

Share

Next:

Latest news

-

Premium Stainless Steel Hose Clamp - Durable & Rust-Proof

NewsAug.24,2025

-

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025