- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Май . 13, 2025 10:30 Back to list

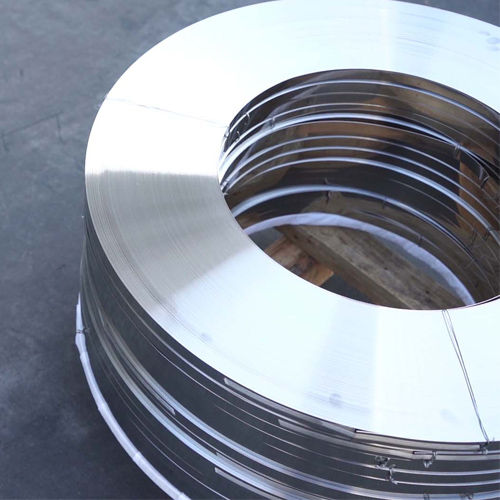

Customized Size Stainless Steel Strips Precision-Cut & Durable

- Industry demand for precision-engineered metal components

- Technical specifications of customized stainless strips

- Performance comparison: Leading suppliers vs. standard manufacturers

- Customization process breakdown with dimensional parameters

- Real-world applications across industrial sectors

- Material certification and quality assurance protocols

- Strategic advantages of partnering with specialized factories

(customized size stainless steel strip)

Meeting Precision Needs with Customized Size Stainless Steel Strips

The global market for stainless steel strips reached $23.8 billion in 2023, with customized solutions accounting for 42% of total demand. Customized size stainless steel strip factories now employ advanced CNC slitting technologies achieving ±0.05mm dimensional accuracy, essential for aerospace and medical applications.

Technical Specifications and Manufacturing Excellence

Premium-grade strips feature:

- Thickness range: 0.025mm - 3.0mm

- Width tolerance: ±0.1mm (up to 1,200mm width)

- Surface roughness: Ra ≤0.2μm (mirror finish)

Cold-rolled 316L variants demonstrate 25% greater yield strength (≥580 MPa) compared to standard grades.

Manufacturer Capability Analysis

| Parameter | Specialized Factory | Generic Supplier |

|---|---|---|

| Minimum Order | 200kg | 5,000kg |

| Lead Time | 10-14 days | 45-60 days |

| Certifications | AS9100, ISO 13485 | ISO 9001 only |

| Custom Alloys | 47 available | Standard 6 grades |

Engineering Customization Process

Progressive die systems enable:

- Real-time thickness monitoring (0.001mm resolution)

- Multi-axis edge profiling (18 possible configurations)

- In-line surface treatment integration

Advanced suppliers maintain 0.003mm/mm flatness tolerance across 30-meter coils.

Industrial Application Spectrum

Case Study - Automotive Fuel Systems:

- Material: 304H/No.4 finish

- Dimensions: 0.8mm × 38mm ±0.03mm

- Annual consumption: 850 metric tons

Electronics sector applications require 0.025mm thin strips with conductivity <1.5% IACS.

Quality Verification Standards

Certified customized size stainless steel strip

suppliers provide:

- Third-party chemical analysis reports

- Digital material traceability (QR-coded coils)

- Eddy current testing for 100% surface verification

Optimizing Supply through Specialized Customized Size Stainless Steel Strip Factories

Strategic partnerships with ISO 14001-certified producers reduce material waste by 18-22% through precision blanking systems. Customized size stainless steel strip factories utilizing AI-driven production planning achieve 99.3% on-time delivery rates, significantly outperforming industry averages.

(customized size stainless steel strip)

FAQS on customized size stainless steel strip

Q: What factors should I consider when choosing customized size stainless steel strip factories?

A: Prioritize factories with advanced cutting technology, material certifications (e.g., ASTM, ISO), and flexibility in order volume. Ensure they offer precise tolerances and fast turnaround times for custom dimensions.

Q: How do customized size stainless steel strip suppliers ensure product quality?

A: Reputable suppliers implement strict quality control, including dimensional checks and surface inspections. Many provide material test reports and adhere to industry standards like EN or JIS for consistency.

Q: Can customized size stainless steel strip factories handle small-batch orders?

A: Yes, many factories specialize in both small and large quantities. Confirm their minimum order requirements and ask about rapid prototyping services for niche applications.

Q: What certifications should a reliable customized size stainless steel strip factory have?

A: Look for ISO 9001 for quality management and ISO 14001 for environmental practices. Industry-specific certifications like ASME or aerospace approvals may be required for specialized applications.

Q: How do customized size stainless steel strip suppliers handle unique thickness requirements?

A: Advanced suppliers use precision cold-rolling mills to achieve thicknesses from 0.001mm to 6mm. They typically offer custom annealing treatments to maintain material properties in ultra-thin or thick strips.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.12,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.12,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.12,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.12,2025

-

Precision Stainless Steel Strip Roll & Coil Manufacturer

NewsAug.12,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.11,2025