- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Noy . 13, 2024 15:22 Back to list

automotive spring hose clamps factory

Automotive Spring Hose Clamps A Key Component from Factory to Finish

When it comes to the intricate world of automotive manufacturing, every component plays a crucial role in ensuring that vehicles perform efficiently and safely. Among these components, automotive spring hose clamps may not be the most glamorous subject, but they are undeniably essential for the functionality and reliability of automotive systems. This article delves into the significance of these clamps, their manufacturing processes, and their role in the automotive industry.

The Importance of Hose Clamps

Hose clamps are devices used to attach and seal a hose onto a fitting, providing a secure connection that is vital for various systems in an automobile, including the fuel, coolant, and air systems. Among the different types of hose clamps available, spring hose clamps stand out due to their unique design and functionality.

Spring clamps are particularly favored in automotive applications due to their ability to maintain a consistent pressure on the hose, accommodating for thermal expansion and contraction. This ensures that the hose remains secure, eliminating the risk of leaks that could lead to significant mechanical failures. Given the rigorous demands of automotive environments—where fluctuations in temperature, pressure, and vibration are common—spring hose clamps are engineered to maintain reliability under extreme conditions.

Manufacturing Process of Spring Hose Clamps

The production of automotive spring hose clamps involves several key processes, each integral to creating high-quality, durable products. Manufacturing typically begins with the selection of raw materials, which often include stainless steel or other alloys known for their strength and corrosion resistance.

Once the raw materials are sourced, the production process generally includes the following steps

1. Cutting and Shaping The metal is cut into the required dimensions for the clamps. This is followed by shaping the material into the specific design that enables the spring mechanism to function effectively.

automotive spring hose clamps factory

2. Heat Treatment To enhance durability and elasticity, the clamps undergo a heat treatment process. This step is critical, as it ensures that the clamps can endure repeated stress without losing their shape or tensile strength.

3. Surface Finishing After shaping and heat treatment, surface finishing is performed to improve corrosion resistance and aesthetic appeal. This may involve processes like polishing or coating, which help enhance the longevity of the clamp.

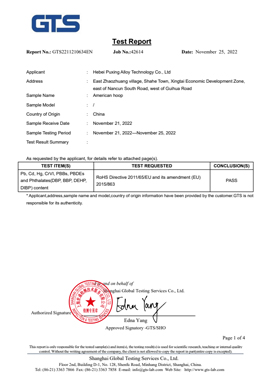

4. Quality Control A thorough quality control process is indispensable in the manufacturing of automotive parts. Each batch of hose clamps is inspected for defects and tested to ensure they meet stringent automotive industry standards.

5. Packaging and Shipping Finally, once the clamps pass all quality checks, they are packaged and prepared for shipment to automotive manufacturers or aftermarket suppliers.

The Role of Factories in the Supply Chain

Automotive spring hose clamp factories play a pivotal role in the overall automotive supply chain. As specialized manufacturers, they not only provide the essential components required by vehicle producers but also contribute significantly to continuous innovation within the industry.

By investing in advanced manufacturing technologies, such as automation and computer-aided design (CAD), these factories improve efficiency and precision in the production of hose clamps. Furthermore, many factories are increasingly adopting sustainable practices, reducing waste and energy consumption during the manufacturing process. This not only benefits the environment but also aligns with the growing demand for eco-friendly automotive components.

Conclusion The Unsung Heroes of Automotive Engineering

In conclusion, while automotive spring hose clamps may not be the focal point of automotive engineering discussions, their contribution to vehicle safety and performance is undeniable. The meticulous manufacturing process and continuous improvements in design and materials reflect the importance of these components in ensuring the reliability of various automotive systems. As factories innovate and adapt to the ever-evolving automotive landscape, spring hose clamps will continue to play a vital role in the safe operation of vehicles worldwide. Their durability, efficiency, and reliability make them unsung heroes of the automotive industry, safeguarding performance with every journey.

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025

-

High-Quality T Bolt Hose Clip from Leading Factory & Suppliers Reliable t bolt hose clip Factories

NewsJul.07,2025

-

Mini Hose Clamp Manufacturer & Supplier Precision Hose Clamps Mini Clamp Factory

NewsJul.07,2025