- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Feb . 10, 2025 09:42 Back to list

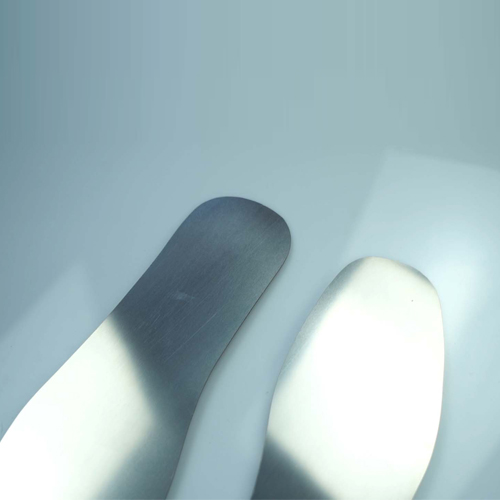

carbon steel strip

The world of carbon steel strips is a tapestry of precision, strength, and versatility, making it an indispensable resource across numerous industries. As a material that has been in use for countless applications, carbon steel strips have proven their irreplaceable role in both industrial and consumer products. Here we delve into the nuanced world of carbon steel strips, bringing together insights from experienced professionals in metallurgy and engineering.

Authorities in industrial applications highlight the significance of quality control in the production of carbon steel strips. Advanced technology and rigorous testing ensure each strip meets stringent industry standards. The process involves precise control over parameters such as thickness variations and surface defects, employing advanced methods like laser measurement to deliver the highest quality product possible. The trustworthiness of a carbon steel strip supplier is often based on their ability to deliver consistent quality and meet evolving customer needs. It's not just about the raw material itself, but also about the support and knowledge that a supplier can provide. A trusted supplier is one who assists clients in selecting the right grade of steel, provides guidance on storage and maintenance, and delivers products in a timely fashion, ensuring a seamless integration into their production processes. In the realm of product innovation, carbon steel strips are at the forefront, inspiring new applications and efficiencies. Engineers are continually exploring ways to incorporate these strips into emerging technologies and eco-friendly solutions, such as renewable energy components and green building materials. This forward-thinking approach not only leverages the intrinsic qualities of carbon steel but also aligns with global sustainability goals. In summary, the enduring appeal of carbon steel strips lies in their unparalleled utility, expert engineering, and the trust established between suppliers and users. For industries demanding high-quality materials that offer both performance and reliability, carbon steel strips remain an unrivaled choice. Whether it’s through improving the efficiency of production or contributing to innovative green technologies, the continued evolution of carbon steel strips is set to play a crucial role in the future of engineering materials.

Authorities in industrial applications highlight the significance of quality control in the production of carbon steel strips. Advanced technology and rigorous testing ensure each strip meets stringent industry standards. The process involves precise control over parameters such as thickness variations and surface defects, employing advanced methods like laser measurement to deliver the highest quality product possible. The trustworthiness of a carbon steel strip supplier is often based on their ability to deliver consistent quality and meet evolving customer needs. It's not just about the raw material itself, but also about the support and knowledge that a supplier can provide. A trusted supplier is one who assists clients in selecting the right grade of steel, provides guidance on storage and maintenance, and delivers products in a timely fashion, ensuring a seamless integration into their production processes. In the realm of product innovation, carbon steel strips are at the forefront, inspiring new applications and efficiencies. Engineers are continually exploring ways to incorporate these strips into emerging technologies and eco-friendly solutions, such as renewable energy components and green building materials. This forward-thinking approach not only leverages the intrinsic qualities of carbon steel but also aligns with global sustainability goals. In summary, the enduring appeal of carbon steel strips lies in their unparalleled utility, expert engineering, and the trust established between suppliers and users. For industries demanding high-quality materials that offer both performance and reliability, carbon steel strips remain an unrivaled choice. Whether it’s through improving the efficiency of production or contributing to innovative green technologies, the continued evolution of carbon steel strips is set to play a crucial role in the future of engineering materials.

Share

Next:

Latest news

-

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025