- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 23, 2024 23:32 Back to list

316 hose clamps factory

The Evolution and Importance of 316 Hose Clamps in Industrial Applications

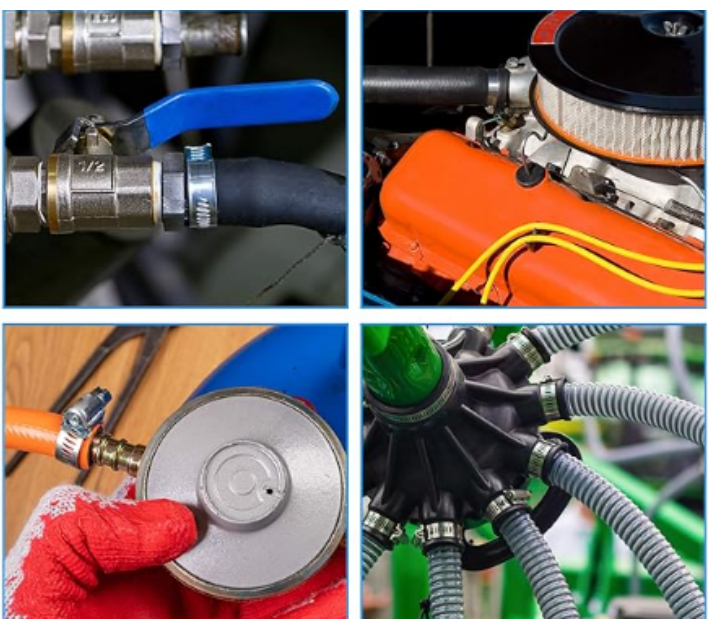

Hose clamps are essential components in a wide range of industrial and commercial applications. Their primary function is to secure hoses onto fittings, ensuring a leak-proof connection. Among the various materials available for hose clamps, 316 stainless steel stands out due to its superior properties. This article delves into the significance of 316 hose clamps, the reasons for their popularity, and their factory production processes.

Understanding 316 Stainless Steel

Before exploring the specifics of hose clamps, it is important to understand the nature of 316 stainless steel. This steel alloy is composed of iron, carbon, nickel, and chromium, with molybdenum added to enhance its resistance to corrosion, particularly in chloride environments. As a result, 316 stainless steel is often referred to as marine-grade stainless steel, making it ideal for applications in coastal or saline environments.

Advantages of 316 Hose Clamps

The use of 316 stainless steel in the manufacturing of hose clamps offers numerous advantages

1. Corrosion Resistance One of the most significant benefits of 316 hose clamps is their resistance to rust and corrosion. This is especially critical in applications where hoses are exposed to harsh weather conditions or corrosive substances.

2. Durability 316 stainless steel hose clamps are designed to withstand high pressure and temperature fluctuations. Their sturdy construction ensures longevity, reducing the need for frequent replacements and maintenance.

3. Versatile Applications These hose clamps are suitable for a variety of industries, including marine, chemical processing, food and beverage, and pharmaceuticals. Their ability to perform reliably across different environments makes them a versatile choice for manufacturers and end-users alike.

4. Hygienic Properties In industries where cleanliness is paramount, such as food processing or pharmaceuticals, 316 stainless steel's hygienic properties help prevent contamination. The smooth surface of the clamps also facilitates easy cleaning.

316 hose clamps factory

The Factory Production Process

The manufacturing of 316 hose clamps involves several key steps, from material selection to finishing. Here’s an overview of the factory production process

1. Material Handling The process begins with the careful selection of high-quality 316 stainless steel rolls. These rolls are inspected for impurities and inconsistencies to ensure that only the best materials are used.

2. Cutting and Shaping Once the material is approved, it is cut into appropriate sizes depending on the specifications of the hose clamps being produced. Advanced machinery often shapes the stainless steel into the desired bracket form with precision.

3. Forming and Assembly The cut sections are then bent and formed into the clamp shape. Depending on the design, components such as screws and brackets are attached. Automation plays a significant role in this stage, improving efficiency and reducing labor costs.

4. Surface Treatment To enhance the corrosion resistance and aesthetic appeal of the clamps, various surface treatments such as passivation may be applied. Passivation removes free iron from the surface and enhances the natural oxide layer, providing added protection against corrosion.

5. Quality Control Quality assurance is integral to the manufacturing process. Each batch of hose clamps undergoes rigorous testing to check for durability, tensile strength, and corrosion resistance. This ensures that only top-quality products reach the market.

6. Packaging and Distribution Once the clamps have passed all quality checks, they are packaged for distribution. Proper packaging is essential to prevent damage during transportation and to ensure that customers receive their products in pristine condition.

Conclusion

316 hose clamps exemplify the intersection of innovation and practicality in industrial manufacturing. Their unique properties make them indispensable in various sectors, where reliability and durability are paramount. As industries continue to evolve, the demand for high-quality components like 316 hose clamps will likely increase. Investments in research and technology by clamp manufacturers will further enhance the capabilities and applications of these essential tools, ensuring they remain a cornerstone of modern engineering. The journey from raw material to a finished product highlights not only the complexities of manufacturing but also the importance of quality in ensuring safety and efficiency across diverse applications.

-

High Quality Precision Stainless Steel Strip - GPT-4-Turbo Grade

NewsAug.02,2025

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, High Torque

NewsJul.31,2025